TOUCH AND FEEL AT THE NANOSCALE

SOLUTIONS

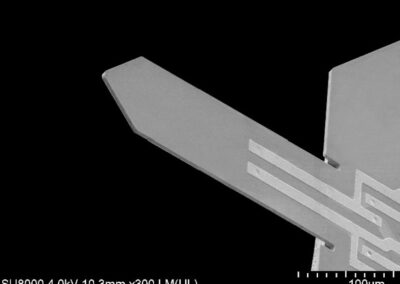

TRILAYER MEMS CANTILEVER TECHNOLOGY

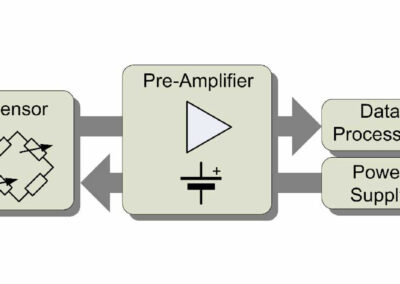

In most of the traditional AFMs, the deflection of the cantilever is detected using the optical beam deflection method where a laser beam reflected from the back of a cantilever is centered on a quadrant photo diode. Integrating electronic and actuation mechanisms into micromechanical devices into MEMS cantilevers an applied force can be transduced to an electrically measurable signal. A high sensitivity is achieved by measuring the resistance of the sensors by means of a Wheatstone bridge.

Employing such so called “self-sensing” cantilever in an atomic force microscope (AFM) allows getting rid of the optical read-out by a laser reflected at the backside of the cantilever.

This opens new applications where there is not enough space for the optical read-out module above the sample to be investigated or where the sample has to be immersed into – even – nontransparent liquids like for biological samples.

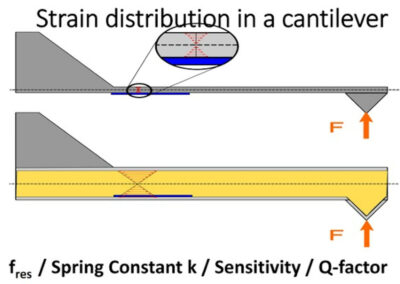

The deflection sensitivity of the self-sensing cantilever increases with its thickness due to the increased distance of the sensors from the neutral axis of the cantilever. However, the spring constant of the cantilever increases strongly with its thickness.

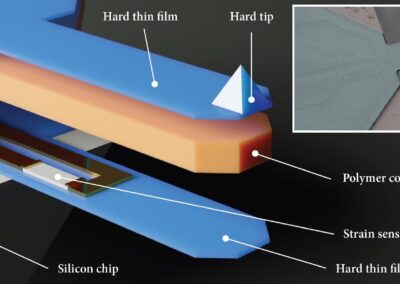

The design of the new tri-layer cantilever incorporates an elastically soft polymer core enveloped by 2 hard thin film layers. This patented new cantilever concept provides additional degrees of freedom to optimize the performance of the MEMS cantilever. The most striking advantages compared to standard Si or SiN self-sensing cantilever are

- For a given resonance frequency f0, the force sensitivity of the trilayer is up to 10 times higher than that for silicon cantilevers.

- The use of a polymer as core of the AFM cantilever increases its bandwidth f0/Q, – Q is the mechanical quality factor. This is particularly advantageous when imaging in vacuum when fluid of air damping is absent. Excellent resolution can be achieved even at imaging speeds up to 10 times higher than with Si or SiN self-sensing cantilever.

- All sensing elements and electrical connections are hermetically sealed inside the MEMS device, which makes the trilayer devices inherently suited for measurements in fluids – even in opaque, electrically conductive or harsh chemical environments.

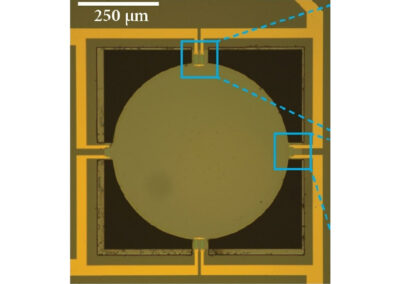

The trilayer technology is not limited to self-sensing cantilevers. Examples are fluid-compatible membrane-type surface-stress sensors or force-sensors with resolution in the nN-range.

For a detailed description see “A hybrid polymer / ceramic / semiconductor fabrication Platform for high-sensitivity fluid-compatible MEMS devices with sealed integrated electronics” by Nahid Hosseini et al. (arxiv_2307.05221)

STARTER KIT

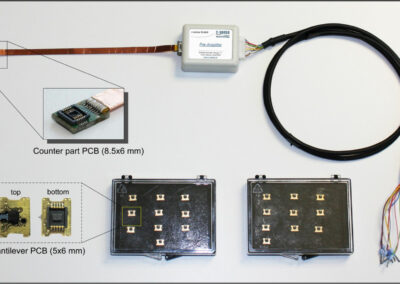

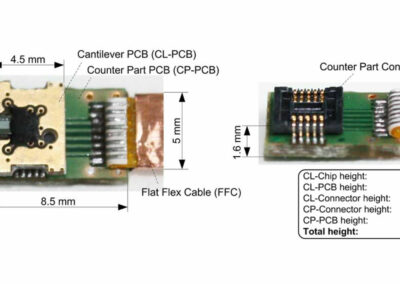

Self-Sensing Starter Kit

The Self-Sensing Starter Kit includes a pre-amplifier, connection cables and 10 pieces of cantilevers to get easily started. The core element of c-sense self-sensing starter kit is the pre-amplifier. It supplies a Wheatstone bridge based sensor with a stable and low noise reference voltage and amplifies the bridge output signal.

CUSTOMIZED CANTILEVER SENSORS

In order to guarantee the greatest possible flexibility for individual problems of our customers, c-sense offers customized cantilevers. We are also open to potential new cantilever developments. Do not hesitate to contact us.

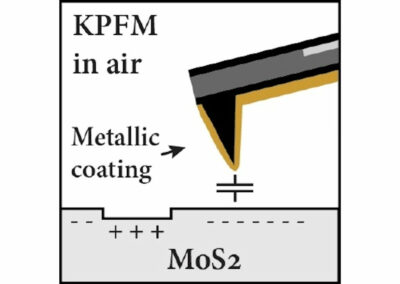

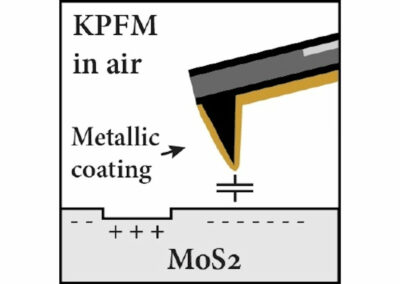

Conductive Cantilevers

To perform conductivity measurements and electrical probing c-sense offers gold coated cantilevers that allow for measurements of small areas and are further suitable for methods like Tip Enhanced Raman Spectroscopy (TERS). For enhanced stability tips grown out of tungsten or platinum/gold are also available.

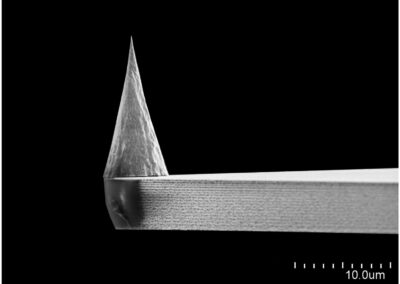

Diamond Tips

For Nanoprobing, scratching experiments and highly demanding topography measurements cantilevers with single crystal diamond tips (SCD) are the perfect fit due to high stability, hardness and endurance.

SENSOR MODULES

Adapters enable all electric measurements with standard AFMs:

Keysight Addon 5500:

The Keysight 5500 add-on was developed for the use of self-sensing technology in a regular optical atomic force microscope. This AFM is widely used in research and industry and can be converted from an optical AFM to a purely self-sensing All Electric AFM using the add-on. There is no damage to the microscope, so you can switch between optical and self-sensing mode at any time. This eliminates the need to purchase an expensive AFM and enables laser-free measurements using your existing microscope with many advantages for various applications.

Bruker Addon:

Bruker is world’s leading AFM manufacturer. Since Bruker’s AFMs are exclusively designed for optical cantilevers, some applications for these products are fundamentally ruled out. The implementation of an adapter enables the use of self-sensing technology in a Bruker AFM. This extends the application range to measurements in non-transparent liquids and facilitates easy cantilever handling. This can be of great advantage especially in the fields of biology, biochemistry and cell research, without having to forego the advantages of conventional optical cantilevers.

Contact us:

Diese Website ist durch reCAPTCHA geschützt und es gelten die Datenschutzbestimmungen und Nutzungsbedingungen von Google.